Aluminum is the material for lightness and strength

Aluminum is a fascinating material with enormous versatility for innovative lightweight construction. State-of-the-art hybrid vehicles, robust mountain bikes, complex engine units: they all rely on high-quality aluminum components. Especially in industries for which every gram saved counts, this material is of particular importance.

Questions?

Our value chain

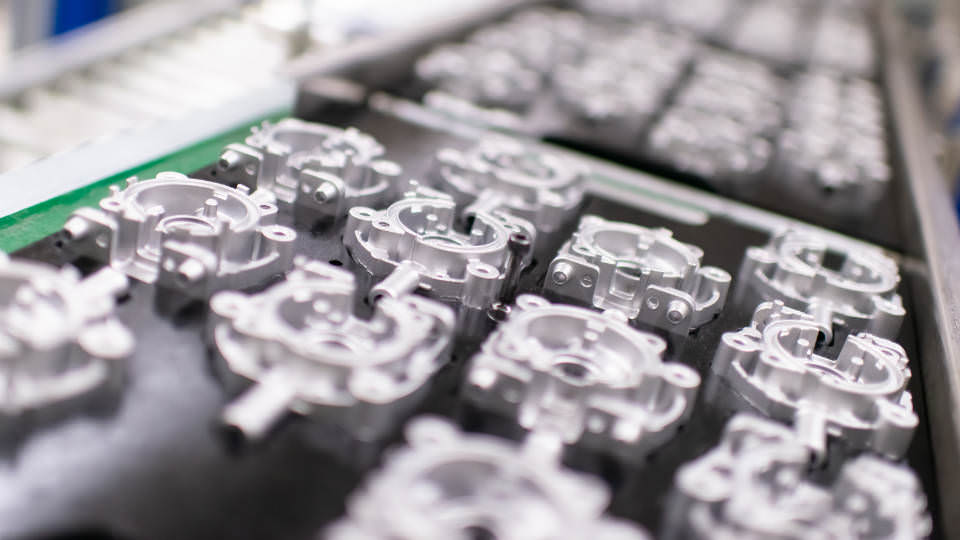

Depending on the application, we finish our products after casting. Our value chain ranges from precision CNC machining to surface treatment at external surface treatment by external certified suppliers or our Inhouse powder coating to the pre-assembly of subassemblies. We deliver ready-to-assemble components directly to our customers' assembly lines.

More about our servicesAluminum die casting: From liquid metal to high-performance components

With over 30 Die Casting machines, our production facilities produce complex and sophisticated castings for a wide range of applications, processing 7,000 metric tons of aluminum annually.

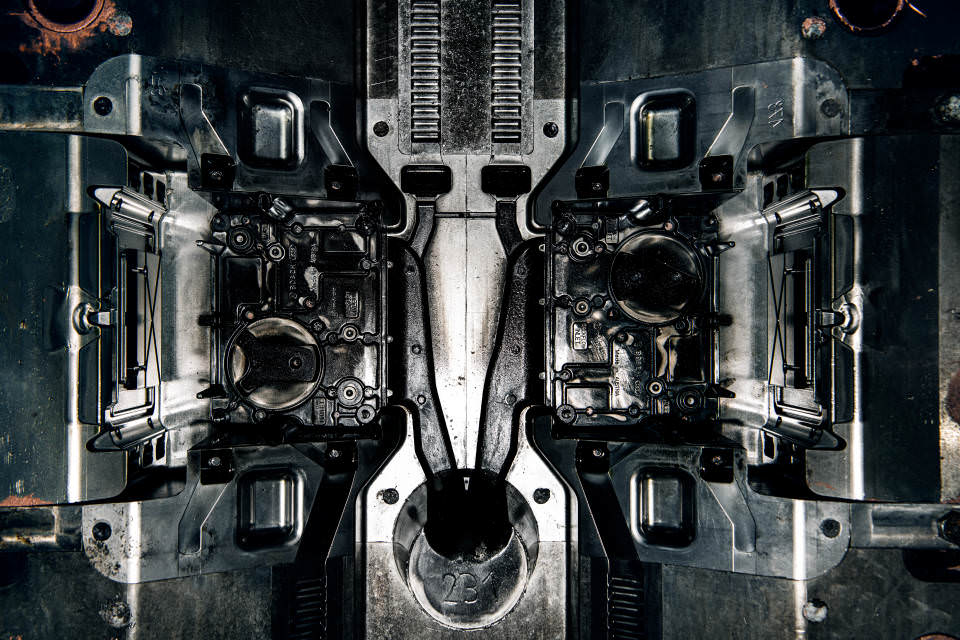

At around 750 degrees celsius, we melt the aluminum ingots supplied, then cast them later in moulds. Once the material is liquified, it is cast at a pressure up to 200 Pa and up to 430 kilometres per hour into the steel casting mould. We use machines with a clamping force of 400-1200 tons. Usually several parts are cast at the same time. Our die casting services at a glance:

- Clamping force of the machines: 220 to 1,200 t

- Post-compression (squeezing) of die cast parts

- Vacuum-assisted Die Casting

- Special alloys

- Die Casting alloys available as standard:

- AlSi12

- AlSi9Cu3

- AlSi12Cu1

- AlSi10Mg

- AlSi12CuNiMg

Natural, lightweight, resistant and recyclable

Aluminum is a natural raw material, the third most abundant metal and occurs almost everywhere on earth – around eight percent of the earth's crust is made up of aluminum. The material is very resistant and shortly after production, is coated with an oxide layer which prevents corrosion. This makes aluminum an ideal material when a long service life is required. Even applicable in tough applications and in humid environments.

Due to its low weight, the use of aluminum components lowers the fuel consumption of vehicles. Thanks to its durability and 100% recyclability, aluminum often makes more ecological sense in the long term than alternative materials.