Lightweight Battery Housings in a Single Manufacturing Step

The licensed process possesses both the mechanical properties necessary to protect the cells optimally and a flat surface to effectively regulate their temperature. Due to the manufacturing process, the housings are very lightweight and can be produced in just one manufacturing step.

Feel free to contact usSignificant Cost Reduction

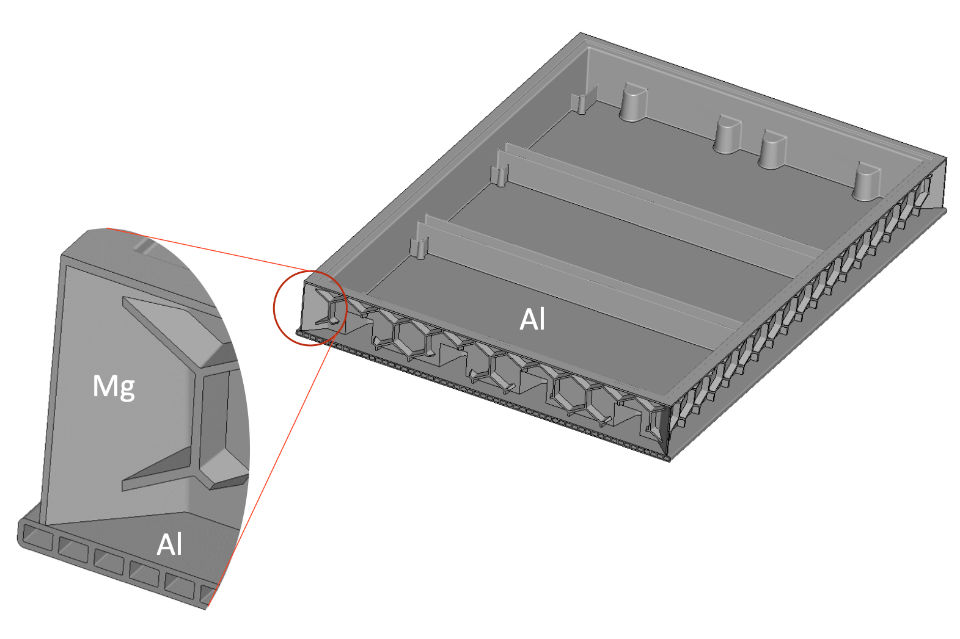

Due to the manufacturing process, the housings are very lightweight and can be produced in a single manufacturing step. This manufacturing step works with various materials, whereby:

- the bottom unit, including integrated cooling channels, is always made of an aluminum extruded profile

- the housing is fixed monolithically through overmolding or joining

- the housing can be made of aluminum, magnesium, or plastic.

The resulting component is very lightweight, extremely robust, and can be manufactured in an integrated manufacturing step without requiring further processing. This elimination of manufacturing steps leads to a significant cost reduction.

Combine best of extrusion with best of casting

Extrusion

- Good flatness

- Low Cost at big surfaces

- Cooling Channels

- Corrosion resistance

Casting

- Complex shapes

- Integration of functionality

- Introduce light weight magnesium

Thixomoulding – Overcasting

- Strong bonding without additional material

- Smart alternative to gluing, screwing, riveting or welding

- Fast process, very short cycle time

- Flexible due to exchangeable casting tools or partial inserts

- Easy to automate with high productivity

Preparation

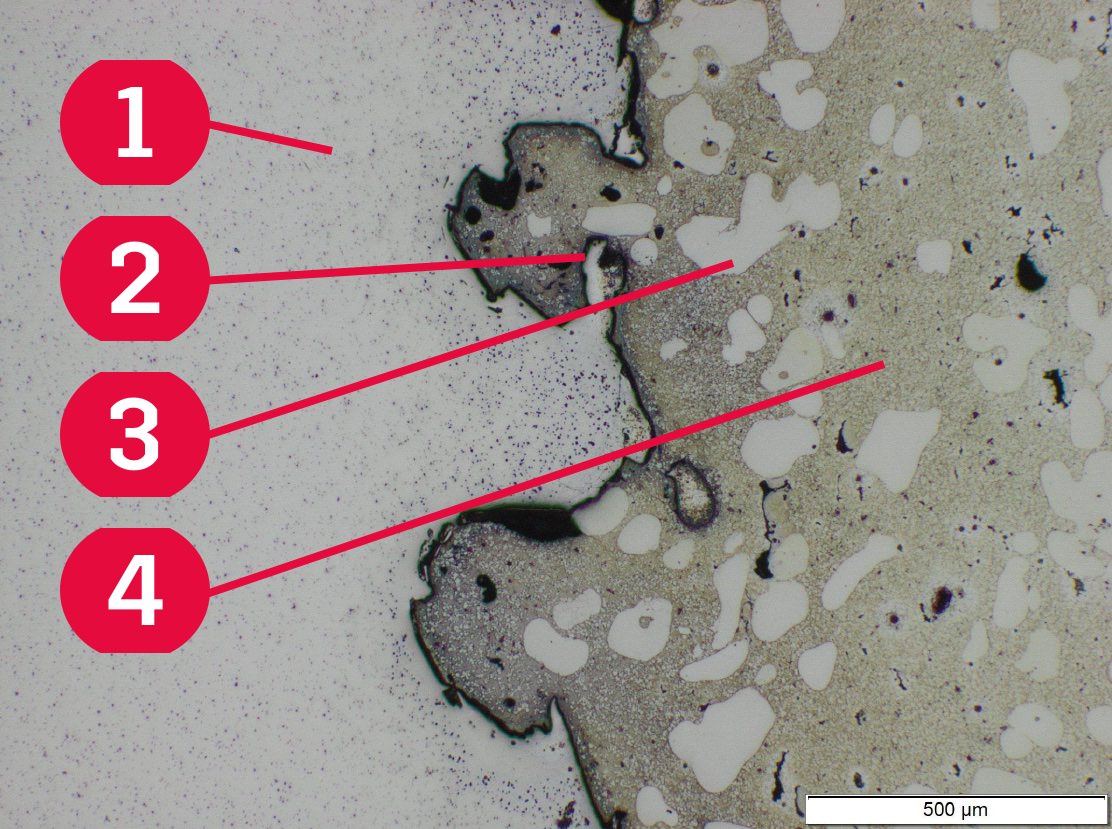

In a pre-process step, the base material is structured by a laser, activated and coated.

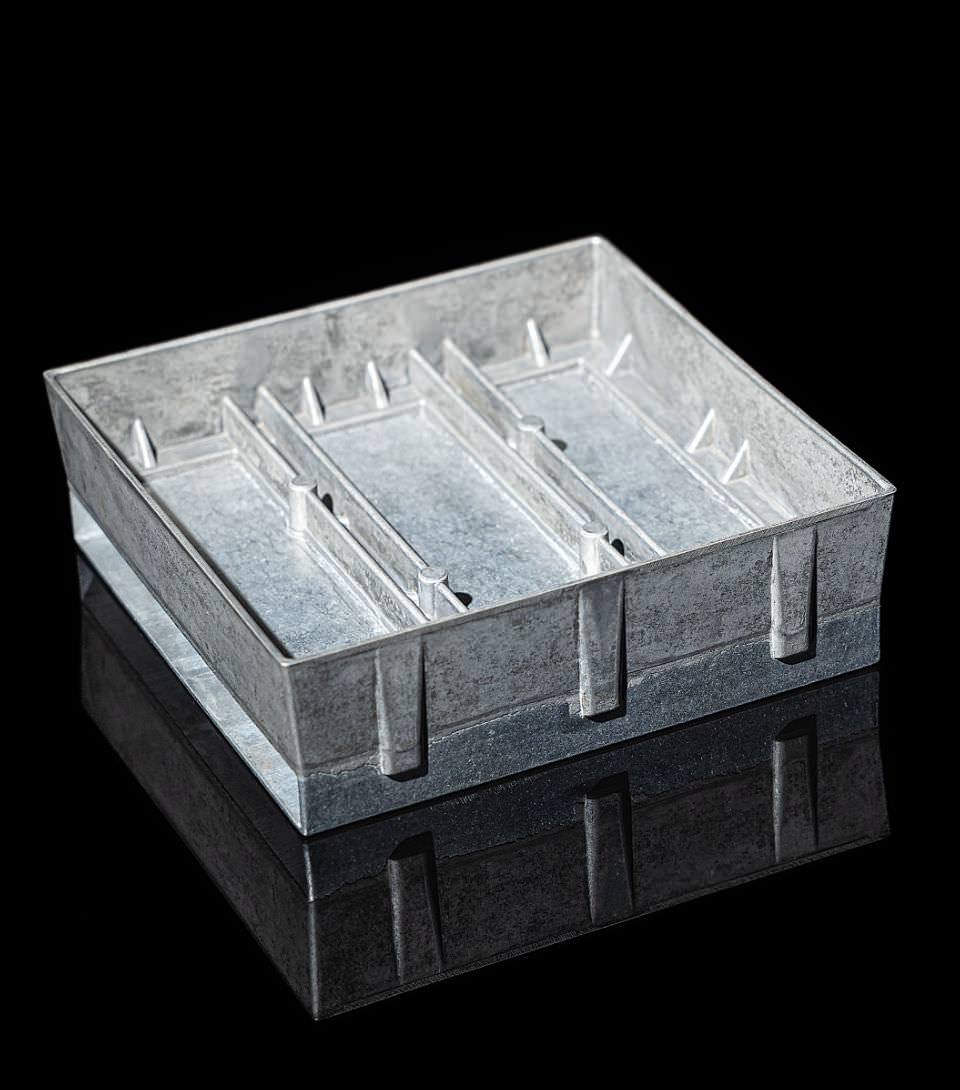

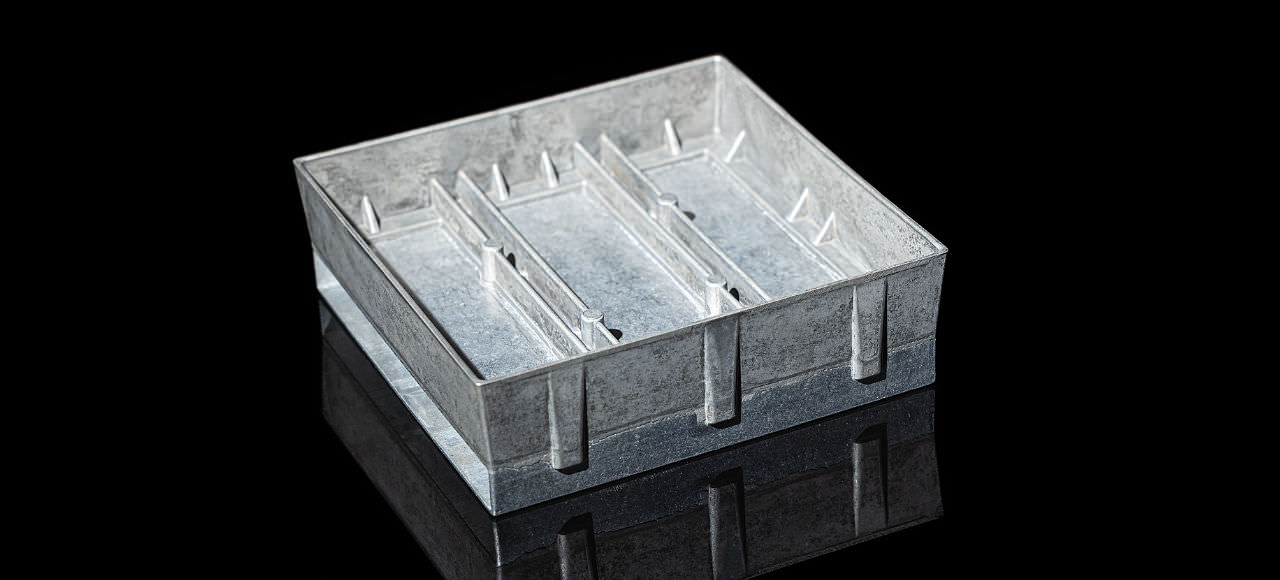

Casting

The components are joined together at the structured surface. The magnesium alloy flows into the cavities and anchors itself.

Cooling and Ejection

After over molding, the metal cools down very quickly. The joint is immediately loadable.

Test results using the Thixomolding Process

- Alumium profile

- Anchor / back cut

- Thixomolding solid particles

- Magnesium casting

Laser treatment

- 3-5 s/cm2

- Multiple Lasers can be used in parallel

Summary

- Endplates can also be cast with our MgCarbonit91 alloy

- By integrating functions, production steps and thus costs can be omitted

- A weight reduction of over 50% compared to previous methods is realistic

- A bionic design counteracts the typical swelling effect

- An electrically non-conductive coating makes it possible today to omit the intermediate layers that are necessary