Careful groundwork is the cornerstone of a successful product

The development of your product is the first step, to a successful precisely fitting end product. Together with your engineers we carry through your ideas and work out the basis for a high-quality and cost-efficient series production, optimising design and the ideal material for your application. From the initial steps of processing we pay special attention to reduce CO2 emissions as much as possible.

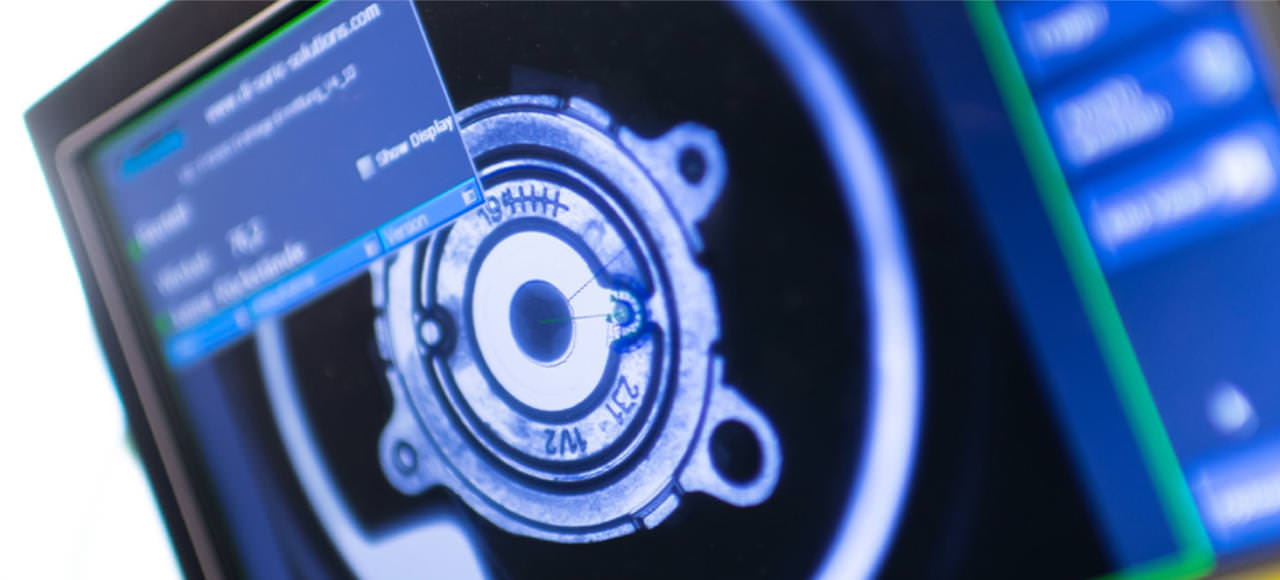

Simulation with a Digital Twin

If the product is manufactured using the new magnesium thixomolding process, we use a Digital Twin (DT) right from the start of the project. This is a simulation in which the real production process is converted into a Digital Design Model, therefore enabling us to visualise, validate and optimise systems and processes in advance, thus, extensively tested in a virtual environment.

With the help of the DT we reduce errors and faults in real processes and accelerate optimisations. In process development, a Digital Twin already offers decisive competitive advantages.

Contact usTools and programmes

We use the following tools and programmes in the development process:

- CAD design

- CAM technology

- Mould and tool making

- Rapid prototyping

- Component redesign

- Mould filling simulation

- Design of die-casting tools and special cutting devices

CAD programs

Naturally, we are able to import and/or convert all standard CAD programs, for example:

- Solid Edge 3D

- Inventor + Mechanical Desktop

- ZW 3D

- Unigraphics NX

- and others (via the formats .stp / .dwg / .igs / catia / proE)